Non-negative pressure variable frequency constant pressure water supply equipment is a new type of clean, sanitary, efficient and energy-saving water supply equipment, also known as the pipe network superimposed pressure water supply equipment. The equipment is fully enclosed structure, no need to build any form of pool, avoiding secondary pollution of water supply. Stainless steel steady-flow regulating tank of food hygiene grade is directly connected with water supply pipeline as water storage buffer device. The original pressure energy of water supply network is fully utilized. Under the same water supply demand, the pump and control equipment with less power can be selected for non-negative pressure variable frequency water supply. At the same time, the municipal water pressure is used to supply water directly without starting the pump under the condition of small water flow at night. Compared with the traditional water supply equipment with pool, the equipment saves a lot of energy and equipment investment, and its energy-saving effect can be as high as 50%. During the operation, the vacuum eliminator equipped with the steady flow regulating tank can automatically eliminate the negative pressure on the pipeline network during the operation of the equipment, ensuring that the normal water supply is not affected by the equipment to other users of the municipal pipeline network. Non-negative pressure variable frequency water supply is a high-efficiency and energy-saving water supply equipment, especially suitable for urban water supply more stable and sufficient occasions.

Performance characteristics

1. The equipment optimizes and integrates many advanced technologies, such as vacuum suppression technology, fluid control technology and intelligent frequency conversion technology, so that the water supply equipment can be directly connected with the municipal water supply pipe network to achieve stable pressure, energy conservation, health, safety and reliability, no negative pressure, no need to build a pool or water tank.

2. Constant pressure. High quality frequency converter and microprocessor are used to dynamically adjust the system time and time, and the pressure precision is controlled in the range of (+0.01Pa).

3. Clean and pollution-free: The equipment is fully sealed, and the system will not enter dust and other impurities. Without water storage facilities, the secondary pollution of water source caused by algae breeding is effectively avoided. The water supply meets the national hygienic standards.

4. Reliable operation. The core components adopt internationally renowned brand accessories, which effectively reduces the failure rate of equipment. And when a pump fails to run, the system automatically shields the fault pump to start the standby pump.

5. High degree of automation and simple operation. After the initialization of the equipment, the unit runs automatically, and after the power cut and the power supply is restored, the unit starts to work automatically. The working pump and standby pump are switched automatically. In case of any fault, an audible and visual alarm will be given in time. The user can find out the cause of the fault directly and quickly through the panel display.

6. Complete control functions. If there are more than one pump unit, the starting mode adopts cyclic soft start, which reduces the impact and interference to the power grid when starting directly, and makes each unit work selectively according to the principle of "first start, first stop, first start", thus prolonging the life of the pump unit. Through the internal clock of the system, the function of timing switch can also be set for timing water supply (such as office area).

7. Water supply can be continued when power failure or system failure occurs. The equipment is directly connected with the municipal water supply network, which maintains the original pressure of the network. Therefore, when power failure or system failure occurs, the equipment can be automatically switched over by-pass pipeline to supply water directly from the municipal water supply network, but the pressure is limited, so it can only supply water to low-rise households.

8. Saving investment. No need to repair pools or water tanks, save the site; make full use of the original pressure of water pipe network, equipment selection power is relatively small, saving equipment investment and follow-up operation power investment; water quality pollution-free, no need to purify equipment and disinfection equipment.

9. Environmental protection and energy saving. The high efficiency and light vertical multi-stage stainless steel water pump is selected as the pressurizing equipment, which can automatically increase or reduce the speed of the pump and control the number of pumps according to the required water volume, and make full use of the original pressure of tap water. The energy-saving rate is as high as 50%-90%.

10. More water-saving. There is no seepage, leaking, leaking and running of the pool, saving water up to 13%. At the same time, it saves water for later cleaning pool.

11. Complete protection functions. It has the protection functions of overload, over current, short circuit, phase absence, over voltage, under voltage and water shortage.

12. Easy to install. After installing the pool and the interface, the equipment can be operated after it is sent to the site to connect the intake pipe and fix the foot screw.

Application occasion

In order to ensure the effective use of the equipment, it is generally required that the water pressure of the municipal water supply network should not be less than 0.12 MPa, and that it can meet the large water consumption per hour. If the gap between the two is small, it can be maintained by a steady-flow regulating tank. If the tap water is insufficient or often shut down, it is suggested that the use of non-negative pressure water supply equipment be carefully considered. Recommend the following occasions to meet the requirements:

1. All kinds of buildings, such as residential quarters, villas, hospitals, schools, hotels, hotels, restaurants, hotels, gymnasiums, golf courses, airports, the army, factory dormitories and other occasions daily water pressurization.

2. Upgrading and energy-saving renovation of old water supply systems (such as water pools or towers, buildings with pneumatic water supply, etc.).

3. All kinds of hot and cold water circulation systems, such as hotels, hotels, schools or factory dormitories, etc.

4. Production and construction, such as factory production and processing, washing equipment, food and beverage processing, construction site and other water supply pressurization.

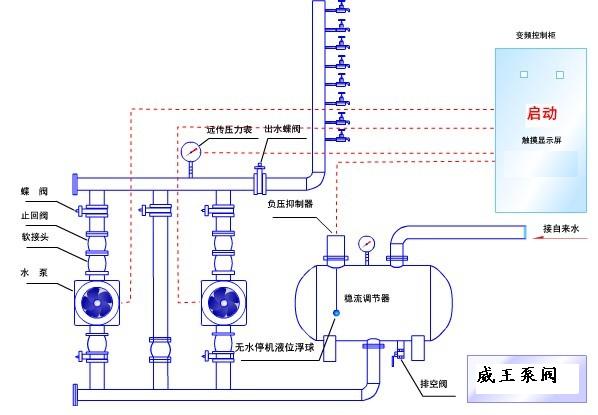

Schematic diagram of working principle:

Performance range