First, the structural characteristics of stainless steel chemical pump :

The pump cover is fixed on the intermediate bracket through the stop, and then the pump cover is clamped in the middle by the connection of the pump body and the intermediate bracket stop. The pump body is axially sucked, radially discharged, and the foot is supported, and can be directly fixed to the base. on. The suspension component is fixedly secured to the intermediate bracket by a stop and supported on the base by a suspension bracket. For the convenience of disassembly, the extension coupling is designed, and the inlet and outlet connection pipes, the pump body and the motor can be removed during maintenance. Simply remove the intermediate coupling of the coupling and exit the rotor assembly for service.

Second, the direction of rotation of stainless steel chemical pump :

The pump is driven directly by the motor through the extension coupling and rotates clockwise as seen from the motor end.

Third, stainless steel chemical pump shaft seal type:

Packing seal: There is a stuffing box inside the pump cover, which is sealed with soft packing. The packing box can be filled with water with a certain pressure for sealing, cooling, lubrication and cleaning.

Mechanical seal: single-end mechanical seal and double-face mechanical seal. The seal chamber is filled with a certain pressure of water, flushing both ends of the friction, and at the same time cooling.

The seal type of the pump adopts packing seal or mechanical seal, which can be applied by users according to requirements. At the same time, it is allowed to adopt the shaft seal type suitable for the sealed cavity size and other structure specified in ISO3069, such as mechanical seal with bellows and impeller seal. and many more.

IH stainless steel chemical pump transport medium temperature is -20 ° C ~ 105 ° C, when needed, double-face sealed cooling device, the transport medium temperature is 20 ° C ~ +280 ° C. Suitable for use in the chemical, petroleum, metallurgical, electric power, paper, food, pharmaceutical, environmental, wastewater and synthetic fiber industries to transport a variety of corrosive or non-contaminating water-like media.

Fourth, the performance range of IH series pumps:

Flow rate Q: 6.3 ~ 400m3 / h Head H: 5 ~ 132m

Speed n: 2900, 1450r/min Banding power: 0.55~110KW

Import diameter: 50 ~ 200mm High working pressure: 1.6Mpa

There are 29 basic types of IH type chemical pumps, of which 22 double speeds (2900, 1450r/min) have been cut into 112 specifications after A and B types of impeller diameter cutting.

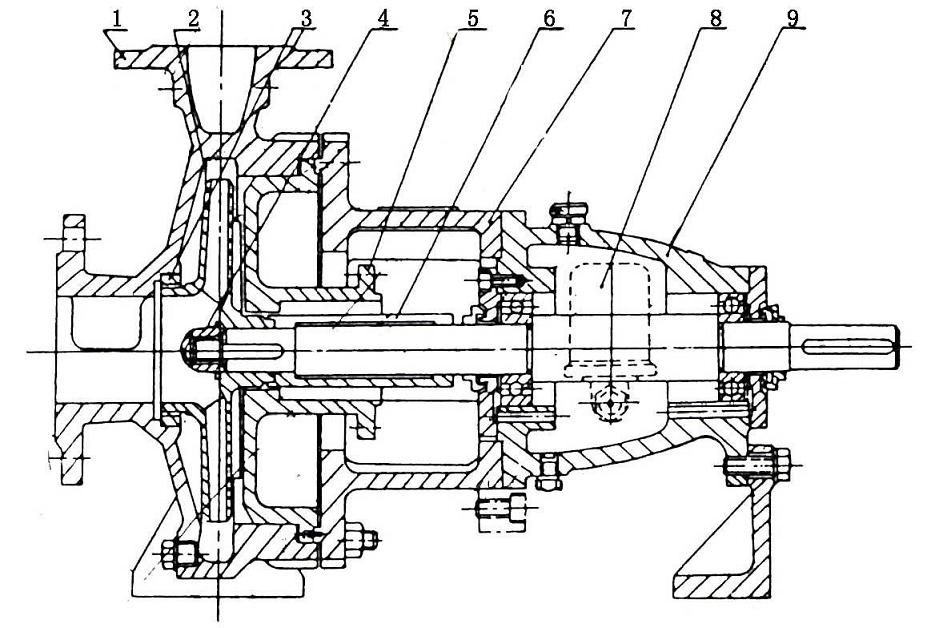

Fifth, the structure chart:

1 Pump body 2 Impeller 3 Sealing ring 4 Impeller nut 5 Pump cover 6 Sealing part 7 Intermediate bracket 8 Shaft 9 Suspension parts

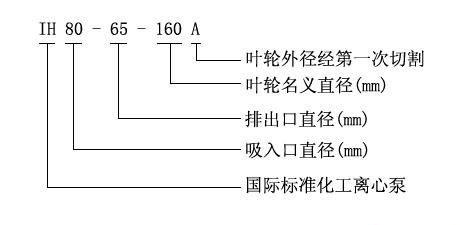

Sixth, model meaning :