The ZCQ type magnetic pump replaces the dynamic seal with a static seal, so that the over-current component of the pump is completely sealed, completely solving the disadvantages of running, running, dripping and leaking which cannot be avoided by other pump mechanical seals. The material of the pump body and the over-current component Made of corrosion-resistant stainless steel, it has the function of CQ [magnetic pump] , and it is self-priming. It only needs to be filled before the pump is used for the first time. Liquid, just turn it on.

In many fields such as petroleum, chemical, pharmaceutical, electronics, etc., more and more manufacturers require a leak-free process environment for the medium they transport, and it is urgent to choose the ideal pump type.

Second, the magnetic pump used

ZCQ series self-priming magnetic pump's overcurrent parts are made of stainless steel (304, 316, 316L), widely used in petroleum, chemical, pharmaceutical, electroplating, environmental protection, water treatment, national defense and other departments, is easy to transport The ideal equipment for burning, explosive, toxic and valuable liquids is a good choice for creating a leak-free, pollution-free civilized workshop. Applicable temperature: -20 ° C ~ 100 ° C.

Third, the leak-proof design

replaces the dynamic seal with a static seal, and uses the magnetic coupling to indirectly drive, completely eliminating the trouble of dripping, and never polluting the use site. It is an ideal pump for eliminating safe, civilized production in the process of chemical industry, eliminating the phenomenon of running, taking off, dripping and leaking, eliminating environmental pollution, creating a “leak-free workshop” and a “leak-free factory”.

IV. Operation principle

ZCQ series self-priming magnetic pump adopts advanced external mixing axial return pump body structure design. The pump body is composed of liquid absorption chamber, liquid storage chamber, volute casing, return hole and gas-liquid separation chamber. See the diagram for the structure). After the pump is started, under the action of centrifugal force, the remaining liquid in the suction chamber and the air in the inlet line are stirred by the impeller to form a gas-liquid mixture, and the mixture enters the gas-liquid separation chamber through the volute, and the gas flow is caused as the flow rate is lowered. Separation, the air is discharged from the pump outlet, and the liquid is returned to the pump chamber through the return hole. After several cycles, the air in the inlet pipe is gradually emptied, so that a certain degree of vacuum is formed in the pump chamber, and the liquid in the lower tank It flows to the pump inlet under the action of atmospheric pressure to achieve self-priming. This series of self-priming process is automatically completed within 1 to 3 minutes of the start of the pump, without manual intervention, when the liquid fills the pump's inlet line and After the pump chamber, the pump group automatically enters the normal operating state. The driving device of the magnetic self-priming pump is directly mounted on the motor shaft by the active magnet coupling, and the impeller rotation on the rotor combination is indirectly driven by the magnetic coupling, and the pump chamber is completely closed, and there is no leakage at all.

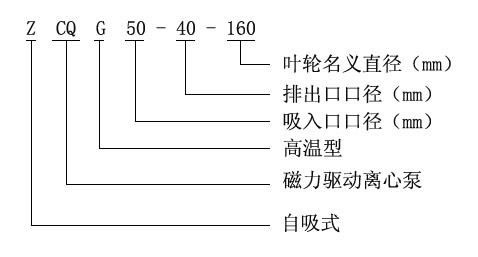

Five, the meaning of the magnetic pump model: