KCB gear oil pump

1. The gear oil pump is suitable for conveying various lubricated liquids. The temperature is not higher than 70 °C. If the temperature is 200 °C, contact with the unit can be used with high temperature resistant materials. The viscosity is 5×10-5~1.5. ×10-3m2/s. 2, gear oil pump is not suitable for transporting corrosive, hard particles or fibers, highly volatile or low flash point liquids, such as gasoline, stupid and so on. The gear oil pump is equipped with a pair of slewing gears in the pump body, and the entire working chamber in the pump is divided into two separate parts by the mutual engagement of the two gears. When the pump is running, the driving gear drives the driven gear to rotate. When the gear is disengaged, a partial vacuum is formed on the suction side, and the liquid is sucked. The sucked liquid fills the respective valleys of the gear and is brought to the discharge side, and the liquid is squeezed out of the pump when the gear enters the meshing. Gear oil pump structure description

This product consists of zero parts and components such as pump body, gear, front and rear pump cover, safety valve, bearing and sealing device.

1. The pump body, front and rear covers and other parts are gray cast iron parts, the gears are made of high quality carbon steel; they can also be made of copper or stainless steel according to user needs.

2. Safety valve.

The 2CY series gear lubrication pump does not have a safety valve itself. Users should install a safety valve in the pipeline system when using it. KCB, 2CY series gear-type oil pump is equipped with a safety valve above the rear pump cover or pump body, when the pump or discharge pipe fails or

When the discharge valve is completely closed to generate high pressure and high pressure, the safety valve will automatically open and remove some or all of the high pressure liquid back.

It is in the suction chamber to protect the pump and pipeline.

3. Bearings.

2CY series gear oil pumps all use DU bearings; tin bronze bearings can be used according to user requirements. &0818.3-83.3, 2CY1.1 gear type oil pump adopts DU bearing; tin bronze bearing can be used according to user requirements.

KCB133-960, 2CY8-60 gear type oil pump has three structures: DU bearing, tin bronze bearing and rolling bearing, which need to be specified when ordering. Those who are not indicated at the time of ordering are supplied in accordance with the DU bearing structure.

The bearings are built-in and rely on the medium being conveyed for lubrication; the 011 bearings and tin bronze bearings work in non-lubricating media.

4. Shaft seal.

The shaft end seals of this series have three structures: skeleton oil seal, mechanical seal and packing seal.

a. Skeleton oil seal: The skeleton oil seal is characterized by convenient maintenance and replacement, low cost, and short life. Dingqing rubber skeleton oil seal is suitable for 1001: the following working environment; fluororubber skeleton oil seal is suitable for working environment below 200 °C.

b. 1 Mechanical seal: The mechanical seal is characterized by reliable sealing, long service life and high cost. The mechanical seal base is made of stainless steel, and the moving and static ring-shaped media are made of YG8 cemented carbide or YG8-graphite, respectively, and the use temperature is below 200 °C.

c. Packing seal: Packing seal is only used for high temperature oil pump, which is characterized by high temperature resistance and a small amount of leakage. During the use, it is necessary to adjust according to the leakage condition. The use temperature is below 250 °C: below.

What type of sealing structure the user needs is specified when ordering. All those who do not indicate when ordering are supplied according to the Dingqing rubber skeleton oil seal structure.

5, inlet and outlet port type:

The inlet and outlet of the 2CY series gear oil pump are the British pipe thread (G) corresponding to the diameter, which is directly made on the pump body.

KCB18.3-200, 2CY1.1-12 gear oil pump is equipped with a waist flange with a pipe screw; the rest of the pump is not equipped with a flange. When the user needs to wear a flange, it should be indicated in the order.

6. The pump and motor are connected by a flexible coupling and mounted on a common chassis.

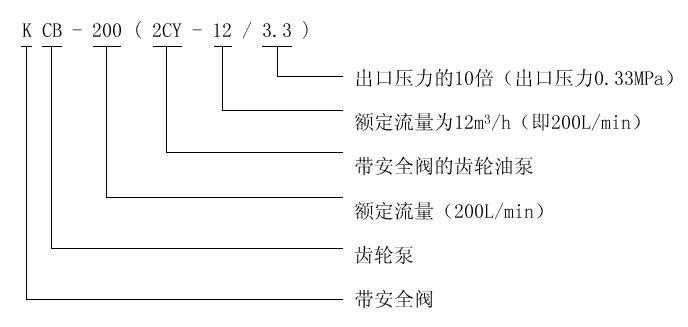

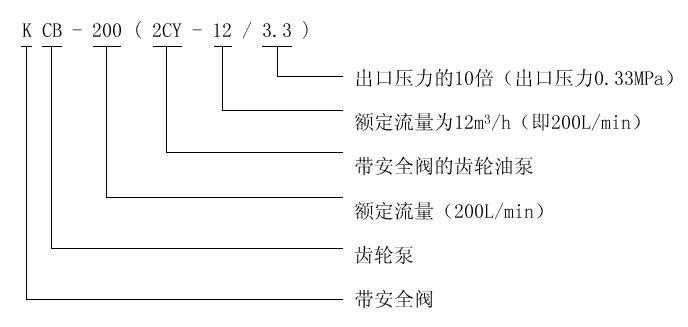

Gear type oil pump model meaning: