GW non-blocking pipe sewage pump Home

>> Products

>> Sewage pump series

GW non-blocking pipe sewage pump Home

>> Products

>> Sewage pump series

-

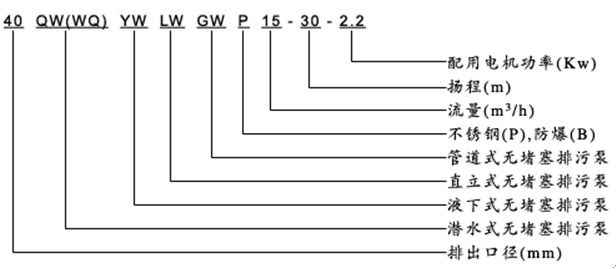

GW non-blocking pipe sewage pump

Model meaning:

Features:

1. The pump and the motor are directly connected coaxially, belonging to the electromechanical integration product, with compact structure and stable performance.

2, large flow channel anti-blocking hydraulic components design, greatly improve the ability of dirt to pass, can effectively pass the pump diameter of 5 times the fiber material and the diameter of the pump diameter of about 50% of the solid particles.

3. The design is reasonable, the matching motor is reasonable, the efficiency is high, the noise is low, and the energy saving effect is remarkable.

4. The mechanical seal adopts hard wear-resistant tungsten carbide, which has the characteristics of durability and wear resistance, which can make the pump run safely for more than 8000 hours.

5, the pump is a vertical structure, the center line of the import and export is on the same horizontal line, and the specifications of the inlet and outlet flanges are the same, and the installation and disassembly are very convenient.

6, small footprint, no need to build a machine room, can save a lot of infrastructure costs; add a protective cover at the motor fan end, the whole machine can be placed outdoors.

Conditions of Use:

A, GW type pipeline sewage pump use ambient temperature ≤ 40 ° C, humidity ≤ 95%; altitude ≤ 1000 meters.

B, the medium temperature does not exceed 60 ° C, the medium weight is 1 ~ 1.3kg / dm3.

C, the use of cast iron material is PH5 ~ 9.

D, stainless steel material can use general corrosive media.

E. The use environment altitude should not exceed 1000 meters. When the above conditions are exceeded, it should be submitted at the time of ordering to provide you with more reliable products.

Note: If the user has special temperature, medium and other requirements, please specify the details of the transport medium when ordering, so that the unit can provide more reliable products.

Product Usage:

1. The discharge of severely polluted wastewater from factories and commercial units.

2. Urban sewage treatment plant discharge system.

3. Sewage drainage system in residential areas.

4. Sewage discharge from hospitals, hotels and high-rise buildings.

5. Subway, basement, and civil air defense system drainage stations.

6. Municipal engineering and discharge of thin mud in construction sites.

7. The water supply system of the water company and the factory.

8. Farm sewage discharge or rural biogas digesters and farmland irrigation.

9. Attached to the exploration mine and water treatment equipment.

10. Water conservancy projects are suitable for water supply and drainage.

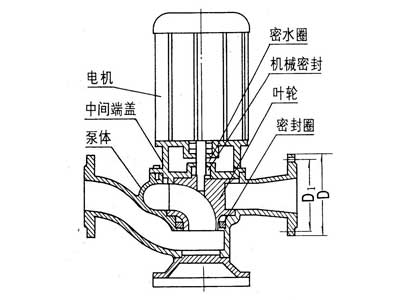

Structure diagram: