G type screw pump

Product introduction:

G-type single-screw pumps are widely used. Most of the foreign single-screw pumps are called “Mono Pumps” and “MONOPUMPS”, which is called “eccentric rotor pump” in Germany. Due to its excellent performance, its application range in China has also expanded rapidly in recent years.

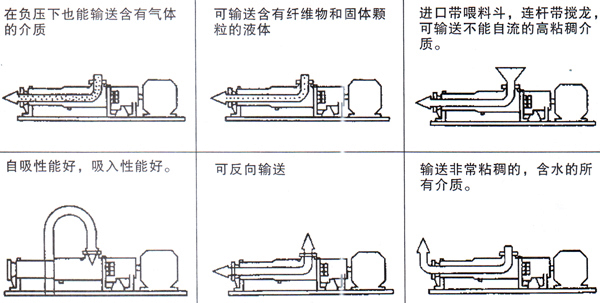

It is characterized by strong adaptability to the medium, stable flow, low pressure pulsation, and high self-priming ability, which cannot be replaced by any other pump.

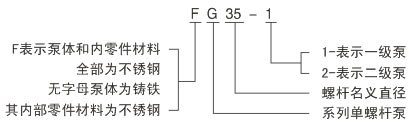

Model meaning:

Working principle and characteristics:

The G-type single-screw pump is a new type of pump that works on the principle of oscillating meshing volume. The main working components are the eccentric screw (rotor) and the fixed bushing (stator). Due to the special geometrical beginning of the part, a separate sealed cavity is formed. The medium is uniformly propelled by the axial flow. The internal flow rate is low and the volume remains the same. The pressure is stable and therefore does not vortex and agitate the product. Single-screw pump is widely used in various industries to transport all kinds of media, constant pressure continuous operation, no pulsation, no damage to the medium conveying, and the flow rate is changed by adjusting the rotating speed to achieve the purpose of metering. This product is suitable for transporting media with high solid content (large particle size up to 150mm) or no solid content | various viscosities (1mPas - 3m mPas) | Thixotropic and easily expandable media | Sensitive medium|Abrasive medium|Medium/non-lubricating medium|Corrosive medium (pH=O-14)|Cohesive medium|Toxic medium|High flow rate, high pressure·Flow range from a few milliliters per hour Up to 500m3 (2200gpm) · Pressure range up to 48bar, special design up to 72bar. The same drive unit can be matched to the rotor/stator of four different designs for a better solution.

Different metal materials are used for different applications, from cast iron and nickel-chromium steel to acid-resistant materials, Hastelloy and titanium alloys. Elastic materials can be selected from wear-resistant, oil-resistant, acid-resistant, alkali-resistant rubber, such as natural rubber, nitrile rubber, ethylene propylene rubber and fluoro rubber. For abrasive media, ceramic or plastic is available. When the medium is not suitable for elastic materials due to high temperature or containing certain chemical components, a hard material stator or a rigid stator may be used. Various shaft seal forms: According to the customer's requirements, the mechanical seal is sealed from a single-end machine (with or without smelting), double-faced machine seals (back-to-back and tandem mechanical seals) to a box seal; , water seal ring and special seal. A leak-free magnetic drive is available for toxic media.

Performance characteristics:

· High suction height can be 6 meters water column

· Two-way rotation, two-way transportation (requires reverse stator)

· Flexible installation method

· Smooth and stable operation, low noise, no pulsation, no shear

, medium temperature range -20 °C~+150°C

· Single-screw pump has few parts, compact structure, small size and easy maintenance. The rotor and stator are the wearing parts of the pump, and the structure is simple and easy to assemble and disassemble. The transmission can be directly driven by a coupling, or by a speed-regulating motor, a V-belt, a gearbox, etc. Haitan Pump Industry is a professional manufacturer of single screw pumps for manufacturing, design and production . Different screw pumps are also used in specific applications.

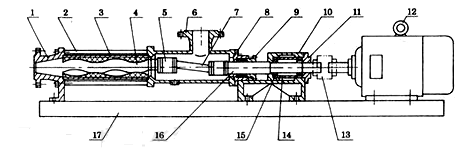

Structure diagram:

|

1

|

Outlet

|

4

|

Screw shaft

|

7

|

Joint axis

|

10

|

Bearing housing

|

13

|

Coupler

|

16

|

transmission shaft

|

|

2

|

Pull rod

|

5

|

Universal joint assembly

|

8

|

Packing seat

|

11

|

Bearing cap

|

14

|

Bushing

|

17

|

Base

|

|

3

|

stator

|

6

|

suction point

|

9

|

Packing gland

|

12

|

electric motor

|

15

|

Bearing

|

|

|

The main purpose:

1. Environmental protection: transportation of industrial sewage, domestic sewage, muddy water containing solid particles and short fibers. Especially suitable for oil water separators, plate and frame filter presses and other equipment.

2. Shipbuilding industry: transportation of media such as wheel bottom cleaning, oil water, oil residue, oil sewage, etc.

3. Petroleum industry: transporting crude oil. In recent years, it has been particularly successful in pumping a mixture of crude oil and water deep underground, a mixture of coal gas and water in the coal field, thereby greatly reducing the cost of mechanical oil recovery and coal mining. When the oil field is late, the use of a screw pump to inject polymer into the formation increases oil recovery.

4, medicine, daily: a variety of sticky pulp, emulsion, various ointment cosmetics and other transport.

5, food canning industry: a variety of viscous starch, cooking oil, bee secret, sugar sauce, fruit pulp, butter, fish oysters and the delivery of their scraps.

6, brewing industry: a variety of fermented viscous liquid, strong wine trough, grain products, various sauces, pulp and mucilage containing solids.

7. Construction industry: spraying and conveying of cement mortar, lime slurry, paint and its paste.

8. Mining industry: underground and slurry water containing solid particles in the mine are discharged to the ground.

9. Chemical industry: various suspensions, greases, various colloidal pulps, various adhesives.

10, printing, paper industry: high-viscosity ink, wallpaper PVC polymer paste and various concentrations of pulp, short fiber slurry transport.

Performance parameters:

|

Type No.

|

Speed

r/min

|

Flow rate

m 3 /h

|

Pressure

MPa

|

Motor

KW

|

Head

m

|

Import

mm

|

Export

mm

|

Allowable particle diameter

mm

|

Allowable repair length

mm

|

|

G20-1

|

960

|

0.8

|

0.6

|

0.75

|

60

|

25

|

25

|

1.5

|

25

|

|

G25-1

|

960

|

2

|

0.6

|

1.5

|

60

|

32

|

25

|

2

|

30

|

|

G25-2

|

960

|

2

|

1.2

|

2.2

|

120

|

32

|

25

|

2

|

30

|

|

G30-1

|

960

|

5

|

0.6

|

2.2

|

60

|

50

|

40

|

2.5

|

35

|

|

G30-2

|

960

|

5

|

1.2

|

3.0

|

120

|

50

|

40

|

2.5

|

35

|

|

G35-1

|

960

|

8

|

0.6

|

3.0

|

60

|

65

|

50

|

3

|

40

|

|

G35-2

|

960

|

8

|

1.2

|

4.0

|

120

|

65

|

50

|

3

|

40

|

|

G40-1

|

960

|

12

|

0.6

|

4.0

|

60

|

80

|

65

|

3.8

|

45

|

|

G40-2

|

960

|

12

|

1.2

|

5.5

|

120

|

80

|

65

|

3.8

|

45

|

|

G50-1

|

960

|

20

|

0.6

|

5.5

|

60

|

100

|

80

|

5

|

50

|

|

G50-2

|

960

|

20

|

1.2

|

7.5

|

120

|

100

|

80

|

5

|

50

|

|

G60-1

|

960

|

30

|

0.6

|

11

|

60

|

125

|

100

|

6

|

60

|

|

G60-2

|

960

|

30

|

1.2

|

15

|

120

|

125

|

100

|

6

|

60

|

|

G70-1

|

960

|

45

|

0.6

|

15

|

60

|

150

|

125

|

8

|

70

|

|

G70-2

|

720

|

45

|

1.2

|

18.5

|

120

|

150

|

125

|

8

|

70

|

|

G85-1

|

720

|

65

|

0.6

|

15

|

60

|

150

|

150

|

10

|

80

|

|

G105-1

|

500

|

100

|

0.6

|

twenty two

|

60

|

200

|

200

|

15

|

110

|

|

G135-1

|

400

|

150

|

0.6

|

37

|

60

|

250

|

250

|

20

|

150

|

Note: 1. The test data of the performance table is made of clean water at 20 ° C and the viscosity is 1 mm 2 / s.

2. When the pump delivers a high viscosity granular medium, depending on the nature of the medium. The pump speed must be different.

3. When the pump delivers different abrasive media, the pump speed must also be different.

Delivery method: