I. Overview of fluoroplastic chemical pump products:

IHF is a single-stage single-suction fluoroplastic alloy chemical centrifugal pump. The pump body is made of metal shell lining polyfluoroethylene propylene (F46). The pump cover, impeller and bushing are all sintered with metal inserts and fluoroplastics. The shaft seal is made of PTFE filling material. Body reinforcement.

The fluoroplastic chemical pump has the advantages of corrosion resistance, wear resistance, high temperature resistance, no aging, high mechanical strength, stable operation, advanced and reasonable structure, strict and reliable sealing performance, convenient disassembly and maintenance, long service life, etc., and is widely used in chemical and pharmaceutical industries. , petroleum, metallurgy, smelting, electric power, electroplating, dyes, pesticides, paper, food, textile and other industries, long-term delivery of any concentration of sulfuric acid, hydrochloric acid, hydrofluoric acid, nitric acid, aqua regia at -85 ° C ~ 200 ° C temperature conditions Strong corrosive media such as strong alkali, strong oxidant, organic solvent and reducing agent are one of the corrosion-resistant devices in the world.

Second, technical parameters:

Flow rate: 6.3 ~ 400m3 / h;

Head: 5 ~ 132m;

Speed: 2900, 1450r/min;

Power: 0.55 ~ 110KW;

Import diameter: 50 ~ 200mm;

High working pressure: 1.6Mpa.

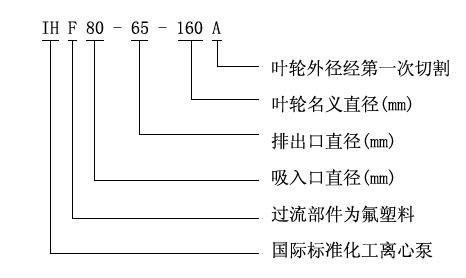

Third, the meaning of the fluorine plastic chemical pump model: